— Standalone Software Solution

Deliver immersive, measurable welding practice using your own compatible hardware—powered by WeldSoft.

— Software-Only Option

A powerful and flexible welding simulation platform designed to deliver skill-based training through realistic virtual scenarios—covering SMAW, MIG/MAG, TIG, and FCAW.This version includes simulation software only, ideal for institutions and training providers with existing compatible hardware.

WeldSoft Application Areas

Realistic simulation for high-throughput, skills-focused technical environments.

Curriculum-aligned modules for classroom integration and student certification prep.

Support reskilling, onboarding, and job readiness with scalable learning tools.

Production-based scenarios designed for welders in fast-paced industrial settings.

Train for complex welds, joint types, and confined spaces in marine applications.

— What’s Inside the Simulator Platform

Software is built to simulate realistic welding conditions, provide measurable feedback, and support structured learning paths across institutions.

Smart management for every user role.

Penetration, porosity and spatter feedback.

Progress & analytics export.

4 different weld types & positions.

Multi-language interface.

— Technical specs, training paths and hardware overview.

— Key Benefits of the Software-Only Version

Core Advantages

— Weld Smarter, Waste Less

Sustainable Training

WeldSoft supports environmentally conscious training with a cleaner, smarter approach to welding education.

Material Savings

Carbon Reduction

Waste Minimization

Technical Specifications

1. Supported Welding Processes

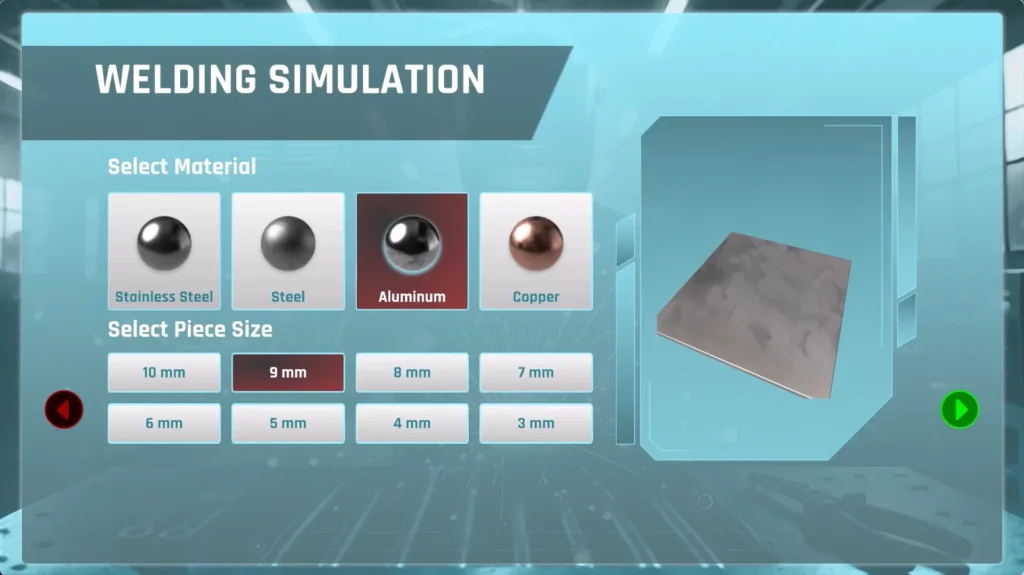

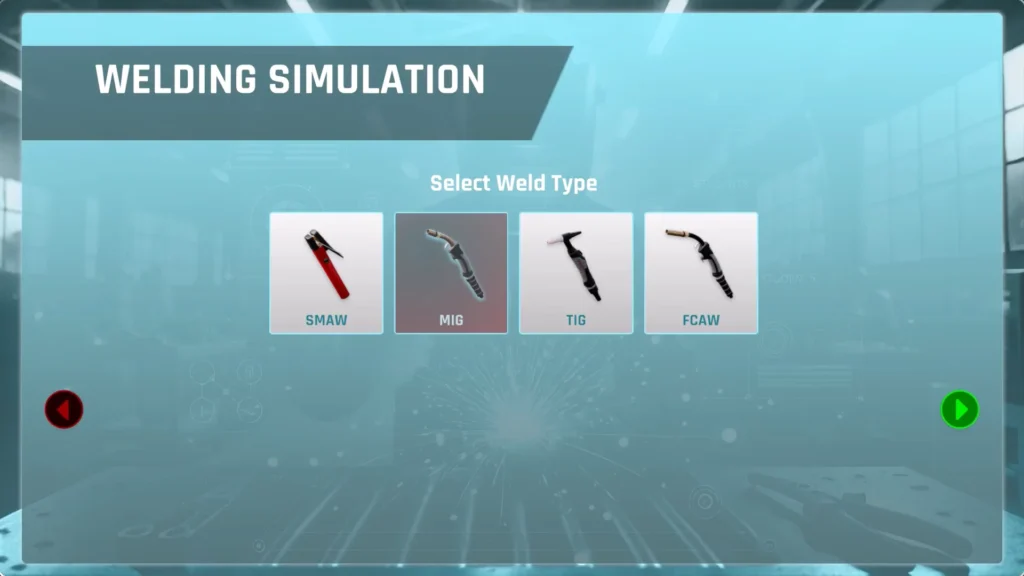

• The system supports four primary welding processes: SMAW (Shielded Metal Arc Welding), MIG/MAG (Metal Inert/Active Gas Welding), TIG (Tungsten Inert Gas Welding), and FCAW (Flux-Cored Arc Welding). These are selectable within the simulation environment and supported by corresponding physical torches.

2. Hardware Components

• The hardware package includes a central control unit responsible for power and system connectivity.

• The welding mask features integrated AR/VR technology and provides a full field of view for realistic simulation.

• Realistic welding torches are included for all supported welding types, offering authentic hand positioning and feel.

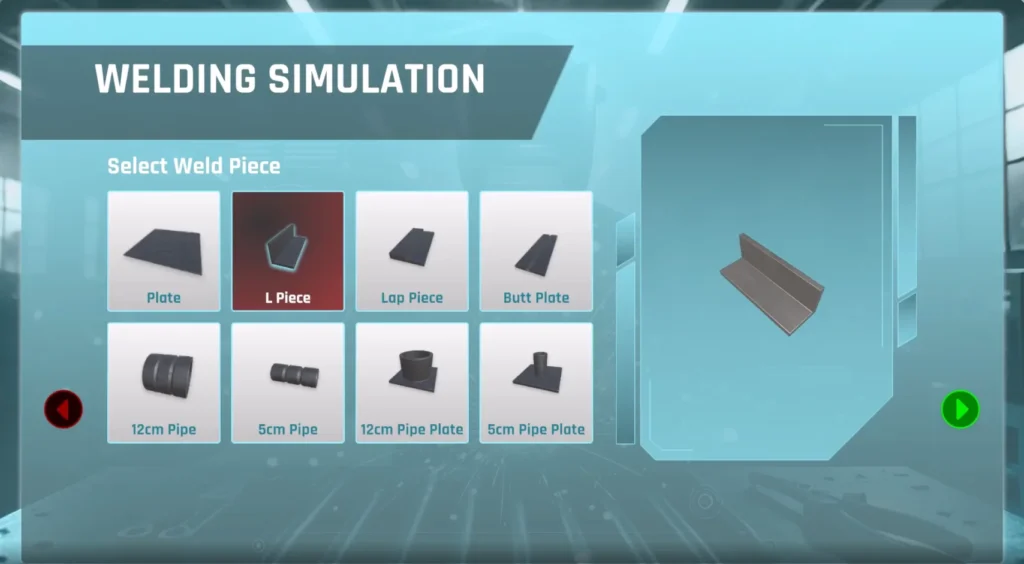

• The workstation is compact, stable, and features adjustable workpieces to simulate different welding angles and tasks.

• Integrated sensors accurately track torch position, angle, movement speed, and distance in real time.

• An external instructor display allows for real-time monitoring and control of training sessions.

• Optional components such as a report printer and LMS integration module are available for extended functionality.

3. Software Features

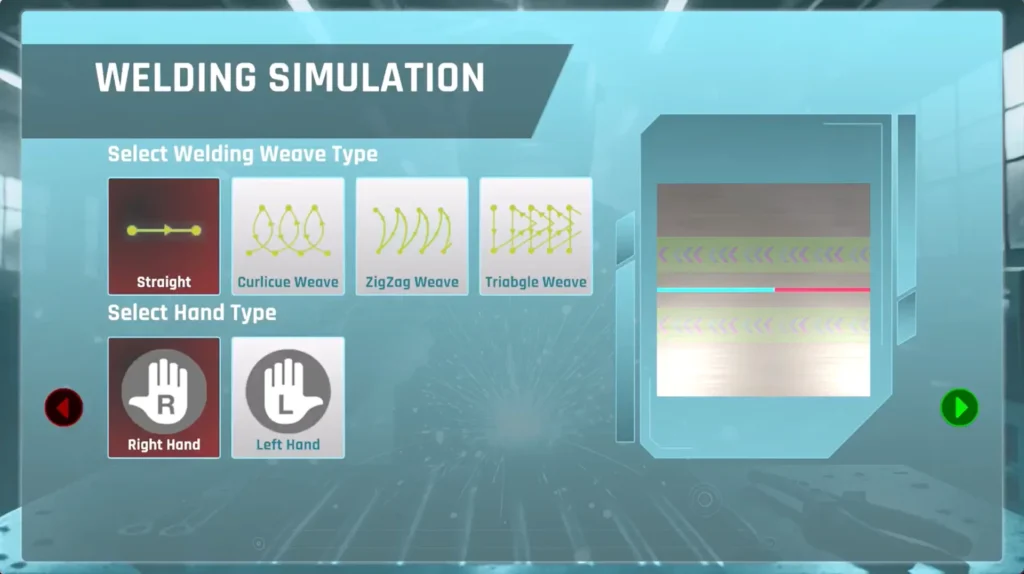

• The simulation engine provides real-time feedback on welding parameters such as penetration depth, porosity, and spatter.

• A role-based user management system enables institutions to organize training through defined access levels (institution, instructor, student).

• The scenario library includes process-specific tasks categorized by joint type, welding position, and difficulty level.

• Progress data is tracked and can be exported as detailed performance reports for evaluation.

• The software supports a multi-language interface, allowing institutions in different regions to operate in their native language.

4. System Requirements and Deployment

• The simulator is delivered in a compact, classroom-ready configuration and is easy to set up and relocate.

• The system operates without the need for consumables such as gas, electrodes, or filler material, allowing unlimited safe practice.

• Standard power requirement: 220–240V AC.

• Recommended ambient temperature for operation is between 10°C and 35°C.

• Intended for indoor use in controlled training environments.

— Let’s discuss how our VR welding simulator can support your training goals. Reach out to our team for a personalized demo or more information.