— Multi-Station Setup

A multi-unit welding simulator package designed for scalable, group-based training across classrooms, workshops and similar learning environments.

— Flexible Deployment

A multi-unit welding simulator package designed for scalable, group-based training across classrooms, workshops, and similar learning spaces. Each student trains independently on their own simulator, while instructors monitor and assess progress individually at each station.

Training Environments

Used for curriculum-based training in technical schools.

Supports hands-on learning in factory or plant settings.

Ideal for reskilling and entry-level job readiness.

Deployed in centralized hubs for large-scale instruction.

Enables flexible training in remote settings.

— What It Enables

Welding Lab Pack provides structure, efficiency, and content consistency for group-based welding instruction—supporting trainers and learners at scale.

Each trainee simulates independently with guidance.

No manual saving needed.

Synchronized content across the space.

Personalized calibration for left or right hand.

Fast deployment with pre-configured system.

— Technical specs, training paths and hardware overview.

— Key advantages of multi-station welding instruction at scale.

Designed to Scale

— Weld Smarter, Waste Less

Sustainable Training

WeldSoft supports environmentally conscious training with a cleaner, smarter approach to welding education.

Material Savings

Carbon Reduction

Waste Minimization

Technical Specifications

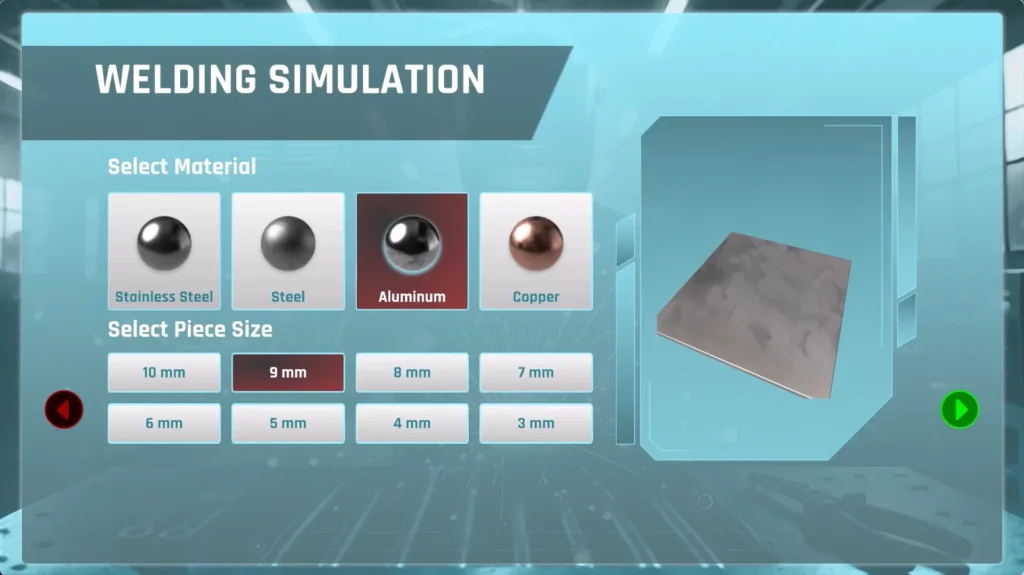

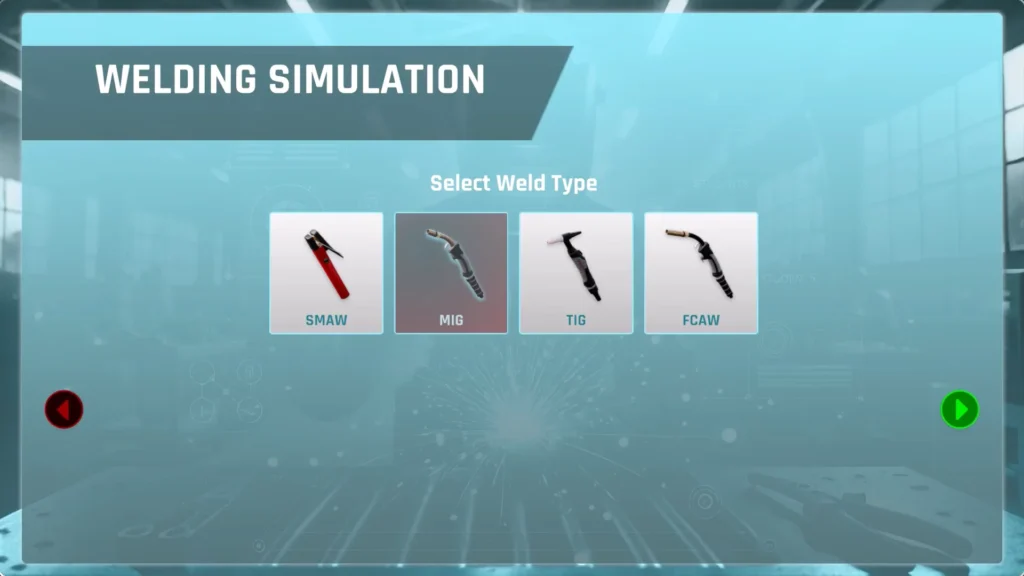

1. Supported Welding Processes

• The system supports four primary welding processes: SMAW (Shielded Metal Arc Welding), MIG/MAG (Metal Inert/Active Gas Welding), TIG (Tungsten Inert Gas Welding), and FCAW (Flux-Cored Arc Welding). These are selectable within the simulation environment and supported by corresponding physical torches.

2. Hardware Components

• The hardware package includes a central control unit responsible for power and system connectivity.

• The welding mask features integrated AR/VR technology and provides a full field of view for realistic simulation.

• Realistic welding torches are included for all supported welding types, offering authentic hand positioning and feel.

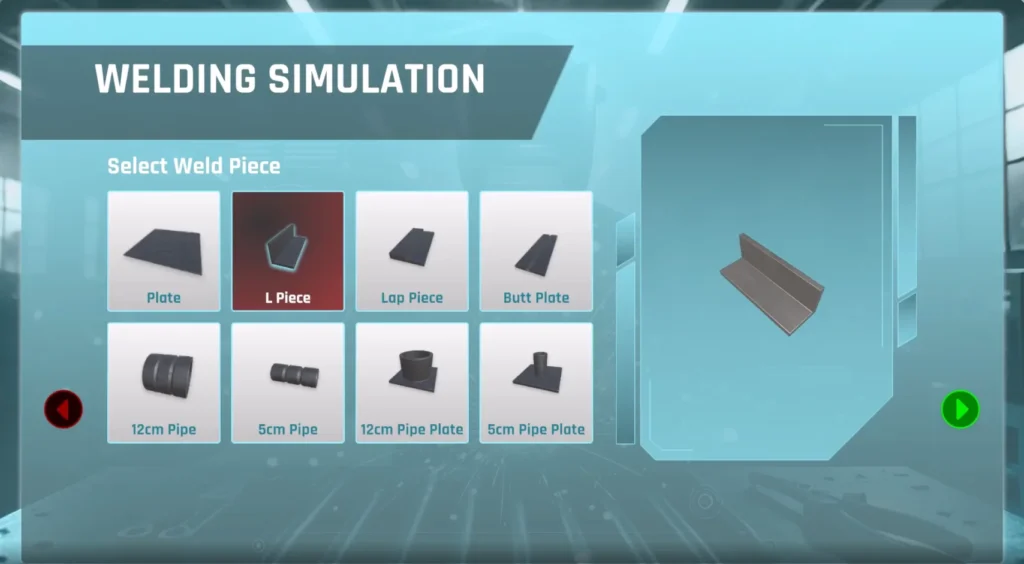

• The workstation is compact, stable, and features adjustable workpieces to simulate different welding angles and tasks.

• Integrated sensors accurately track torch position, angle, movement speed, and distance in real time.

• An external instructor display allows for real-time monitoring and control of training sessions.

• Optional components such as a report printer and LMS integration module are available for extended functionality.

3. Software Features

• The simulation engine provides real-time feedback on welding parameters such as penetration depth, porosity, and spatter.

• A role-based user management system enables institutions to organize training through defined access levels (institution, instructor, student).

• The scenario library includes process-specific tasks categorized by joint type, welding position, and difficulty level.

• Progress data is tracked and can be exported as detailed performance reports for evaluation.

• The software supports a multi-language interface, allowing institutions in different regions to operate in their native language.

4. System Requirements and Deployment

• The simulator is delivered in a compact, classroom-ready configuration and is easy to set up and relocate.

• The system operates without the need for consumables such as gas, electrodes, or filler material, allowing unlimited safe practice.

• Standard power requirement: 220–240V AC.

• Recommended ambient temperature for operation is between 10°C and 35°C.

• Intended for indoor use in controlled training environments.

— Let’s discuss how our VR welding simulator can support your training goals. Reach out to our team for a personalized demo or more information.